Covid-19 birthed Kiiza’s idea of venturing into making PPEs for health workers

When the Covid-19 pandemic broke out in Uganda, as it was elsewhere in the world, frontline health care workers toiled to keep the first wave of patients infected with the virus alive.

The sudden shortages of hand sanitizers, gloves, gowns and face masks, in particular, hampered their efforts and placed their own health in jeopardy.

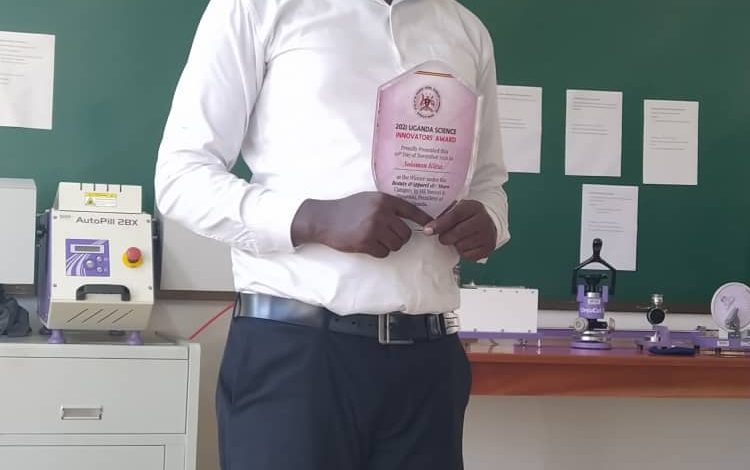

For business minded people like Eng. Solomon Kiiza, 30, a textile engineering graduate, the unprecedented times of exceptional demand were the best chance to do something that would benefit the suffering people.

“The news all over media platforms was of people including frontline health workers lacking personal protective equipment was the order of the day but was so disturbing,” Kiiza said.

He says he quickly thought of filling the supply gap of personal protective equipment (PPEs).

“I realized that these PPEs were being imported from either China or India and were a bit expensive for the public. Something had to be done to change the status quo,” Kiiza says.

He said that in the mix of how to start, he was advised to reach out the Uganda Industrial Research Institute(UIRI) for assistance.

According to Kiiza, the government was willing to support all those who came out with innovations or were willing to support in the fight against the pandemic and that is where the UIRI came in.

“At the government facility, they gave me a team of textile and fashion designers as well as helping me purchase raw materials and the facility to work from,” the 30-year-old fashion engineer says.

He said UIRI was also key in providing laboratory services and fabricating prototypes for the personal protective equipment.

Kiiza explains that after fabrication of the prototypes, it took some time before being cleared for use by the World Health Organisation.

According to the textile engineer, that way, he was able to progress up to the stage of manufacturing the protective gear for use by both the public and the frontline health workers.

“Whereas I have not been to make the products available to the public, everything is set.”

He says he is able to produce overalls, head covers, shoe covers, surgical suits and aprons.

Challenges

Just like any other business, Kiiza says he has faced a number of challenges that he thinks have held him from realizing the full potential of his innovation.

“Funds have been meager yet if funded well, I have the capacity to produce person protective gears that can be used by both the public and frontline health workers. This can see government save a lot of money it injects into importing the PPEs but at the same time create jobs for many young people out there,” he says.

He says that since they are locally manufactured, his PPEs are a bit cheaper than the ones imported from abroad.

“I always find it hard to get raw materials which are from petroleum products but I am optimistic that with Uganda’s oil soon coming out, these will be easy to get locally.”

Making a case for the use of personal protective equipment, Kiiza says these can be used not only during pandemics like Covid-19 but also during normal days by both the public and health workers.

“This means they will continue having market both locally and across the African continent. My goal is to ensure we grow to supply gloves, face masks and other personal protective equipment to many other countries across the continent,” he said.